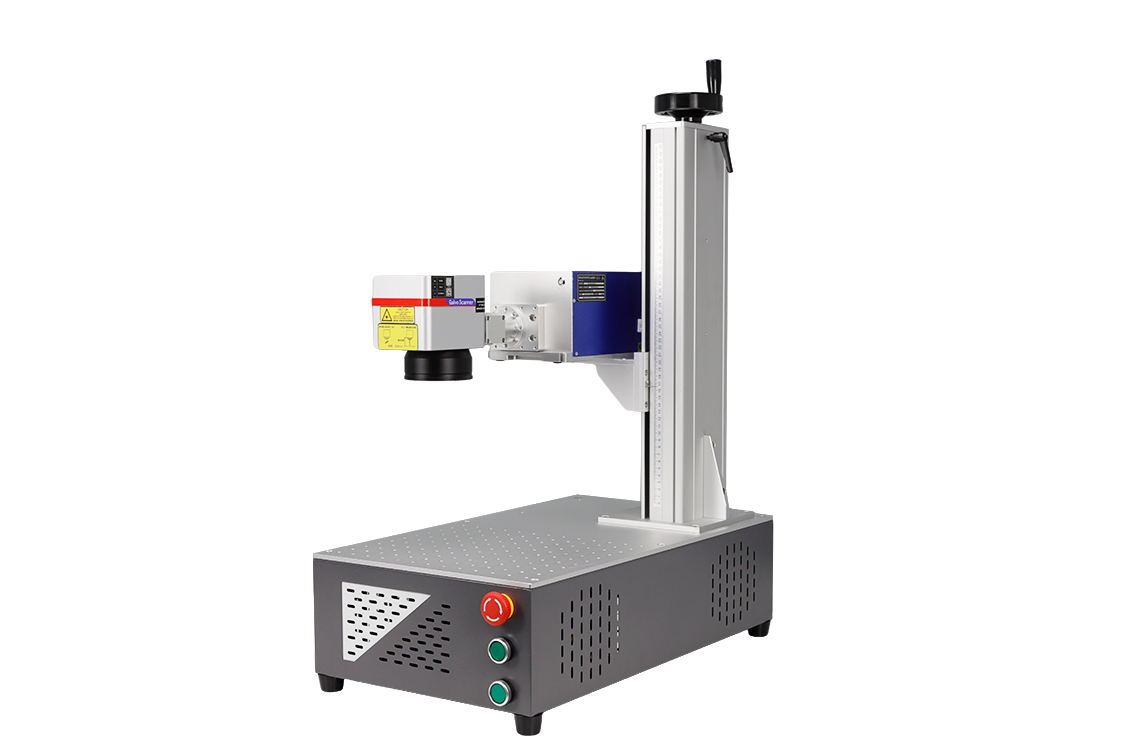

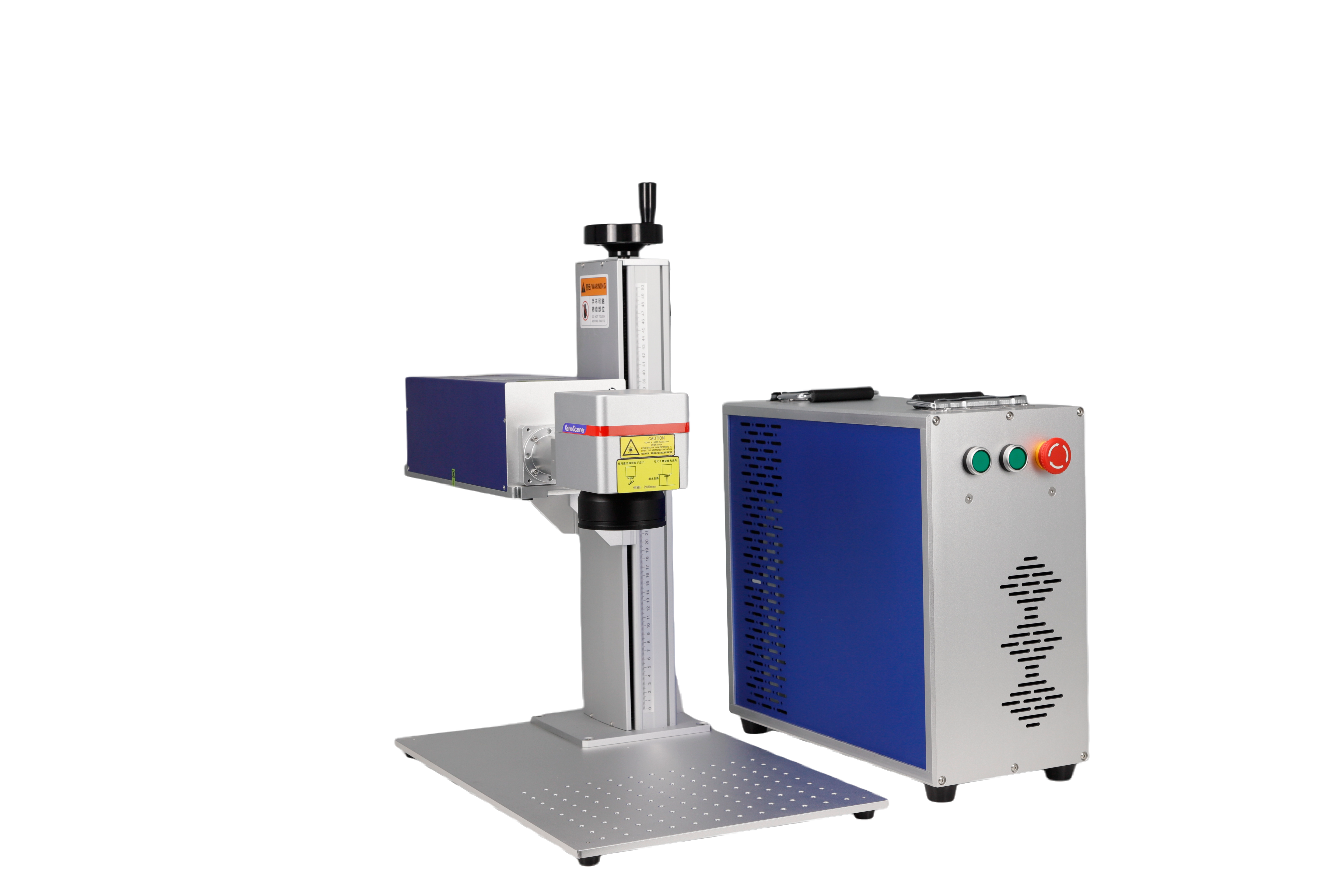

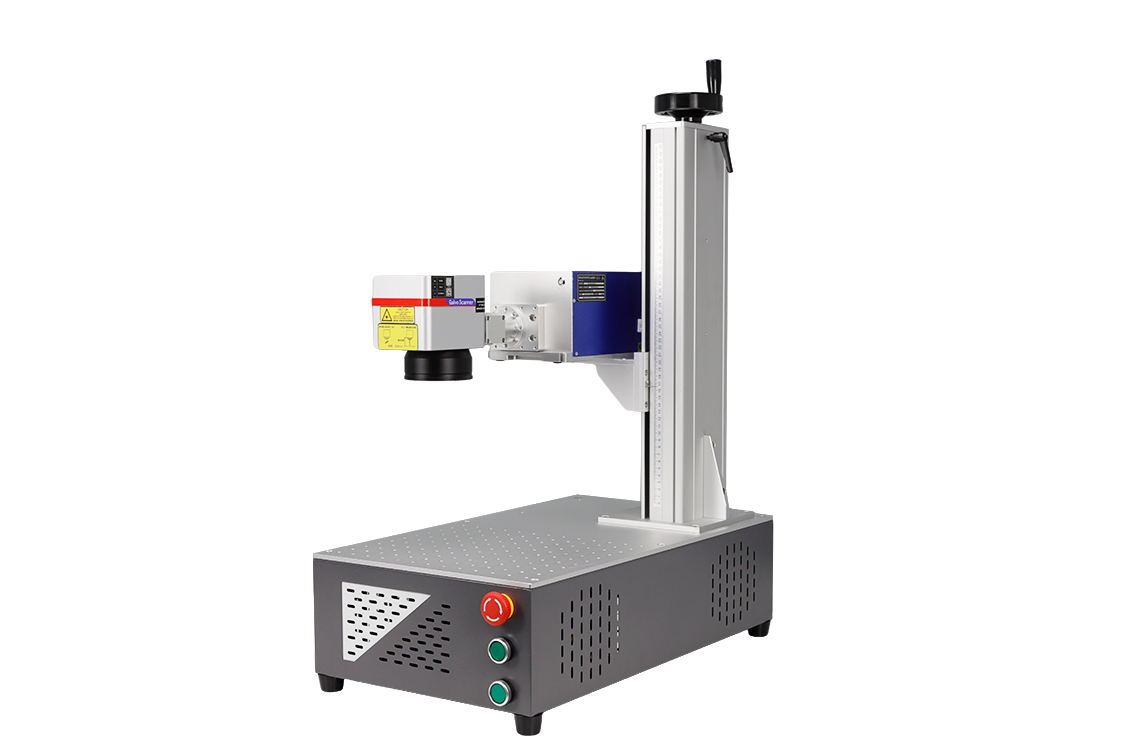

Ultraviolet

Ultraviolet

High-Precision, Cold Processing for Ultra-Fine and Versatile Marking

Technology Overview

The ultraviolet uses a 355 nm ultraviolet laser generated through third-order intracavity frequency doubling. Unlike traditional infrared lasers, the UV laser has an extremely small spot size and operates via cold processing—breaking molecular bonds directly on the material surface without generating heat. This minimizes mechanical and thermal deformation, ensuring ultra-precise and permanent marking results.

Key Advantages

Ultra-Fine Marking & Micro-Engraving

Ideal for detailed graphics, tiny fonts, and high-resolution applications across complex materials.

Minimal Heat Impact

The short wavelength allows cold processing with little to no damage to the surrounding material, preserving the original integrity.

High Beam Quality

Ensures smooth, sharp, and clear marks with excellent contrast and long-term durability.

High Precision & Resolution

The 355 nm laser delivers superior accuracy, making it suitable for delicate surfaces and detailed structures.

High Speed & Efficiency

Fast marking speed enables consistent performance in mass production scenarios.

Supported Materials

Widely compatible with a broad range of materials, including:

Plastics, glass, metal, silicone, wood, bamboo, paper, film, resin, ceramics, leather, acrylic, and more.

Also supports creative marking on natural surfaces like leaves, fruit skin, and handmade paper.

Application Fields

Ultraviolet marking technology is used across high-precision industries and custom processing needs, including:

Electronics: Flexible PCB marking and scribing, micro- and blind-hole drilling on silicon wafers, QR code engraving on LCD glass panels, electronic components.

Medical & Pharmaceutical: Precision marking on drug packaging, medical devices, and polymer bottles with clear traceability and regulatory compliance.

Industrial Manufacturing: High-speed scribing of glass, coated metal marking, surface labeling on communication devices and architectural hardware.

Consumer Products & Packaging: Cosmetic packaging, gift customization, food-grade label marking, and paper-based decorative engraving.

Creative & DIY Applications: Artistic engraving on organic surfaces like leaves, fruit, or paper paintings.

Why Ultraviolet?

Compared to traditional inkjet or infrared laser systems, ultraviolet marking delivers:

✔ Higher resolution and finer detail

✔ No consumables or waste

✔ Eco-friendly, clean processing

Click the button below and get a custom quote

Product Description

Ultraviolet

High-Precision, Cold Processing for Ultra-Fine and Versatile Marking

Technology Overview

The ultraviolet uses a 355 nm ultraviolet laser generated through third-order intracavity frequency doubling. Unlike traditional infrared lasers, the UV laser has an extremely small spot size and operates via cold processing—breaking molecular bonds directly on the material surface without generating heat. This minimizes mechanical and thermal deformation, ensuring ultra-precise and permanent marking results.

Key Advantages

Ultra-Fine Marking & Micro-Engraving

Ideal for detailed graphics, tiny fonts, and high-resolution applications across complex materials.

Minimal Heat Impact

The short wavelength allows cold processing with little to no damage to the surrounding material, preserving the original integrity.

High Beam Quality

Ensures smooth, sharp, and clear marks with excellent contrast and long-term durability.

High Precision & Resolution

The 355 nm laser delivers superior accuracy, making it suitable for delicate surfaces and detailed structures.

High Speed & Efficiency

Fast marking speed enables consistent performance in mass production scenarios.

Supported Materials

Widely compatible with a broad range of materials, including:

Plastics, glass, metal, silicone, wood, bamboo, paper, film, resin, ceramics, leather, acrylic, and more.

Also supports creative marking on natural surfaces like leaves, fruit skin, and handmade paper.

Application Fields

Ultraviolet marking technology is used across high-precision industries and custom processing needs, including:

Electronics: Flexible PCB marking and scribing, micro- and blind-hole drilling on silicon wafers, QR code engraving on LCD glass panels, electronic components.

Medical & Pharmaceutical: Precision marking on drug packaging, medical devices, and polymer bottles with clear traceability and regulatory compliance.

Industrial Manufacturing: High-speed scribing of glass, coated metal marking, surface labeling on communication devices and architectural hardware.

Consumer Products & Packaging: Cosmetic packaging, gift customization, food-grade label marking, and paper-based decorative engraving.

Creative & DIY Applications: Artistic engraving on organic surfaces like leaves, fruit, or paper paintings.

Why Ultraviolet?

Compared to traditional inkjet or infrared laser systems, ultraviolet marking delivers:

✔ Higher resolution and finer detail

✔ No consumables or waste

✔ Eco-friendly, clean processing