well-suited for a wide range of applications

A Versatile and Cost-effective Printing Method

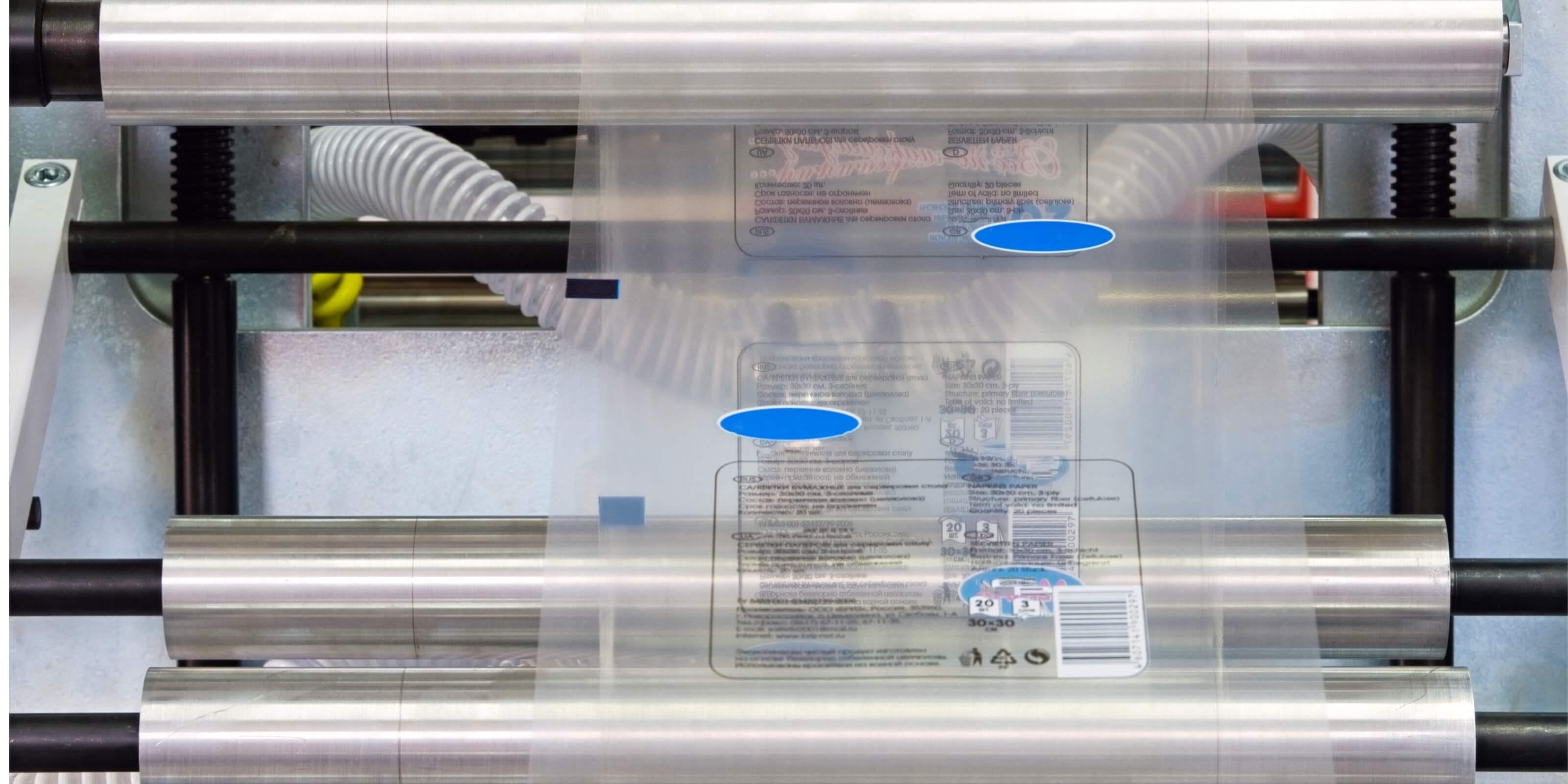

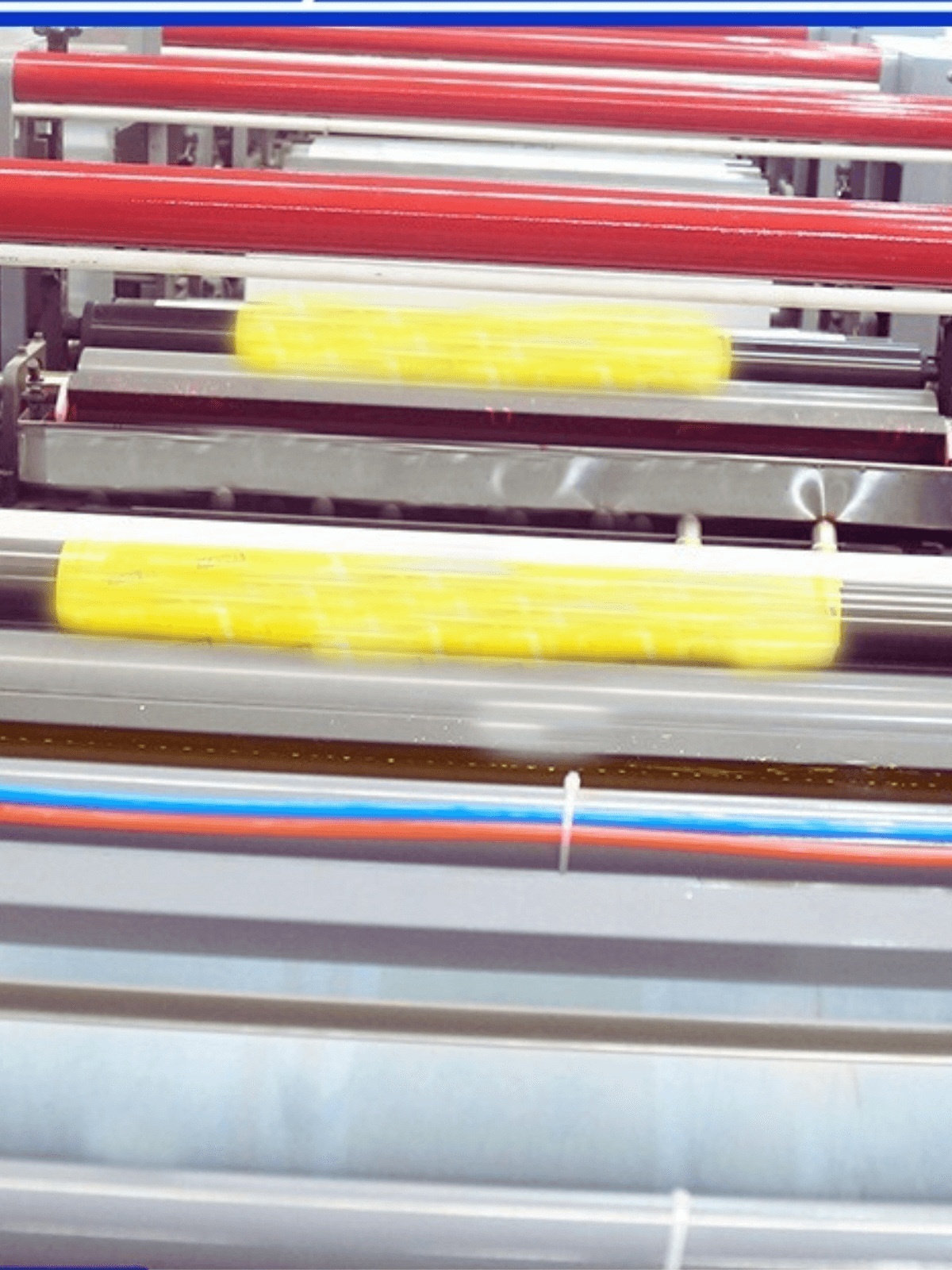

Flexo printing is a printing process that uses a flexible printing plate to transfer an image onto a substrate. This printing method is commonly used for printing on packaging materials, such as cardboard, paper, or plastic film. The printing plate is made from a flexible material, such as rubber or photopolymer, which allows it to conform to the shape of the printing surface. This makes flexo printing well-suited for printing on uneven or curved surfaces.

Flexo printing allows for high-quality printing on a wide range of materials. The printing plate can be easily customized to produce sharp, detailed images, and the flexible nature of the plate allows for printing on surfaces that may be difficult to print on using other methods. Additionally, flexo printing can be done quickly and efficiently, making it a cost-effective option for large printing runs.

Flexo printing is a printing process that uses water-based ink and is suitable for long-run printing jobs. It meets food safety requirements and can be customized with designs featuring 1-14 colors. Flexo printing also has features that increase productivity and efficiency, such as inline rotary die cutting and an automatic web guide for correcting slight alignment variations. It also has a cassette design for quick change and set-up, high efficiency drying capacity, accurate lateral and circumferential registration, stable and accurate tension isolation, and a standard web inspection system to keep track of the printing image. The flexo printing process also has a handy control panel and the ability to add multi-function features. Overall, flexo printing can save paper and lower labor costs while offering a high level of customization and performance.

Compare

Packaging Printing Methods Comparison

All these print methods are used to produce images on a variety of surfaces. Digital and UV printing uses digital technology to directly transfer an image onto a printing substrate, while flexo printing and gravure printing use printing plates to transfer the image onto the substrate.

Cost Efficiency

Setup Time

Plate Setup

Small Volumn

Short

No

Large Volumn

Slightly Long

Yes

Large Volumn

Moderate

Yes

Small Volumn

Very Short

No

Let's Connect