Subheading

Kraft Paper

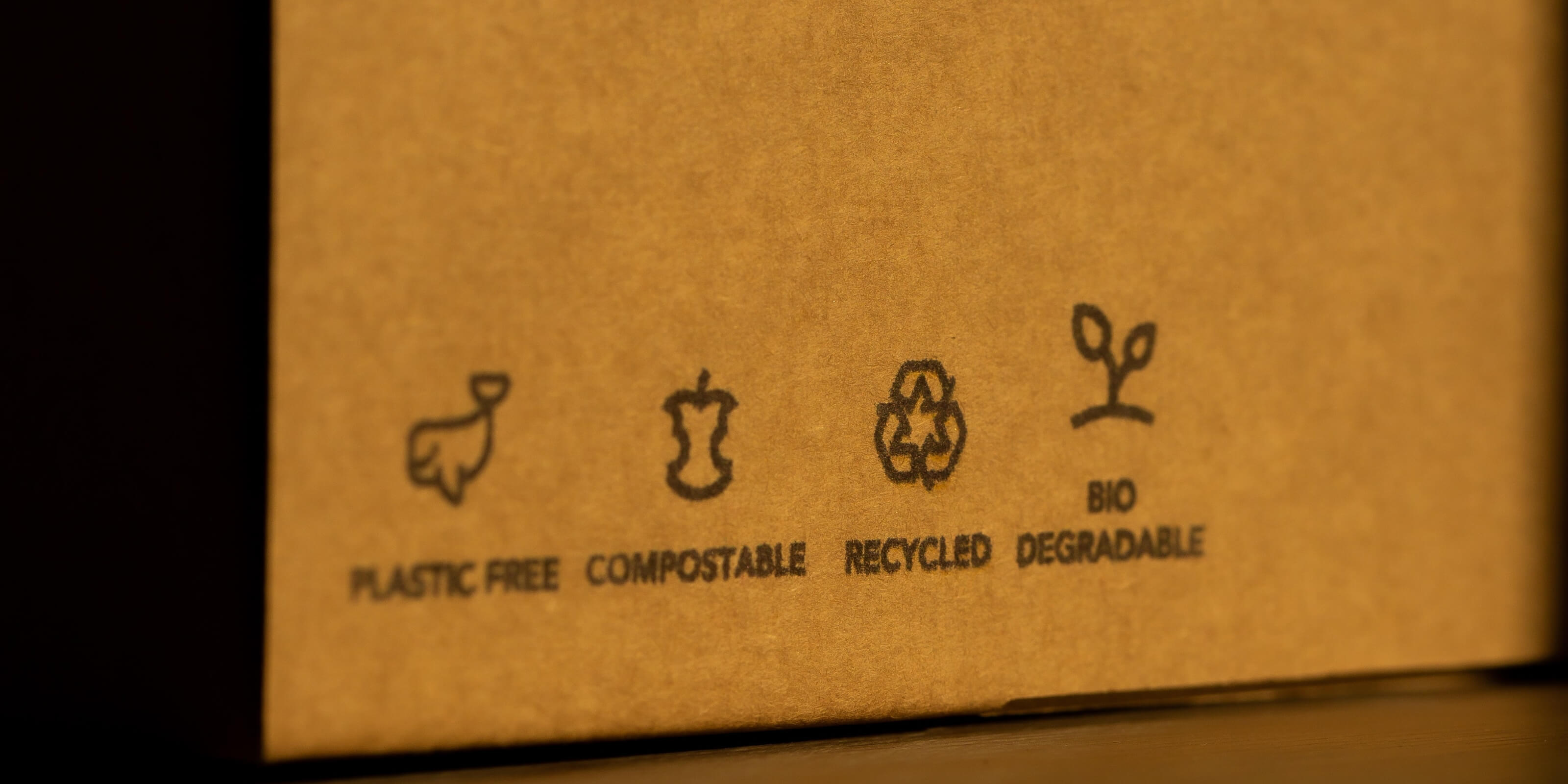

Kraft paper is a type of paper made from wood pulp that comes with better strength and durability. It is commonly used in packaging applications because of its strength and ability to withstand rough handling. Kraft paper is fully compostable, biodegradable and recyclable by itself making it a sustainable option for packaging materials. It is often used to make bags, envelopes, and other types of packaging, as well as for construction and other industrial applications.

Subheading

Heading

Tab 1

Use this text to share information about your brand with your customers.

Tab 2

Describe a product, share announcements, or welcome customers to your store.

Tab 3

Share information about your shipping rates, return policy or contact information.

Use this text to share information about your brand with your customers.

Describe a product, share announcements, or welcome customers to your store.

Share information about your shipping rates, return policy or contact information.

Heading

Use this text to share information about your brand with your customers. Describe a product, share announcements, or welcome customers to your store.

- Resistant to water and chemicals

- 100% compostable, does not break down into particles that cannot be degraded.

- Plant based and reduces

- carbon footprint.

- More expensive than traditional plastics materials.

- Not as smooth and glossy as other types of paper and plastics.

- It is made from wood pulp. The process of making wood pulp can have negative environmental impacts.

Kraft Paper FAQ

Is being plastic free a better choice?

In general, kraft paper is considered to be a more environmentally-friendly option than plastic. Kraft paper is compostable itself, whereas most types of plastic requires additional technology and steps during manufacturing stage. This will significant increase the cost of production to plastics tan to kraft paper. Though that would be the case, plastics has a wide application compatibilities than kraft paper.

However, a extrusion lamination of kraft paper + sustainable plastics will not only deliver sustainability, but also comes up with an at least 60% performance boost. Please read the topic that talks about kraft paper lamination options.

Should I choose kraft paper or bioplastics in terms of sustainability?

Both kraft paper and bioplastic packaging have their own unique benefits and drawbacks. In terms of sustainability, bioplastic packaging and kraft paper packaging can be recycled, composted, and biodegrade. While kraft paper is made under 100% plant based, bioplastics can be either partially or wholly plant based depending on the type of plastics.

In terms of water vapor transmission rate(WVTR) and oxygen transmission rate(OTR), kraft paper and plastics can have very different properties. Kraft paper has a relatively high OTR and WVTR, which means that it allows oxygen and water vapor to pass through it easily. This can be a disadvantage for packaging applications where the product needs to be kept fresh, as the oxygen and water vapor can cause the product to spoil or become stale.

Ultimately, the best packaging option for you will depend on your specific needs and priorities. It may be helpful to consider factors such as the type of product you are packaging, the intended use of the packaging. Please consult us for the best material application to your custom project.

Is something made by wood consider eco-friendly?

Wood pulp, which is the raw material used to make kraft paper, is not inherently environmentally unfriendly. However, the process of making wood pulp can have negative environmental impacts, such as the release of pollutants into the air and water. In addition, the production of wood pulp requires a large amount of energy, which can contribute to greenhouse gas emissions. Furthermore, the use of wood pulp for paper production can lead to deforestation if not properly managed. For these reasons, it is important to consider the environmental impact of wood pulp production and use. Many companies are working to minimize the environmental impact of wood pulp production through sustainable sourcing and the use of renewable energy.