Start

Scale your Next Big Idea

Rotogravure printing is a type of printing process that uses a rotary printing press. It is also known as gravure printing, and it is commonly used for printing on thin materials such as paper, plastic film, and foil. In rotogravure printing, an image is engraved onto a cylinder. The cylinder is then inked and used to transfer the image onto a substrate, such as paper or plastic. The inked image is transferred to the substrate by pressing the cylinder against the substrate and rotating it at high speed. Thus it is suitable for high volumn production.

Rotogravure requires a significant investment in equipment and machinery. Additionally, rotogravure printing is not well-suited for printing on uneven or rough surfaces.

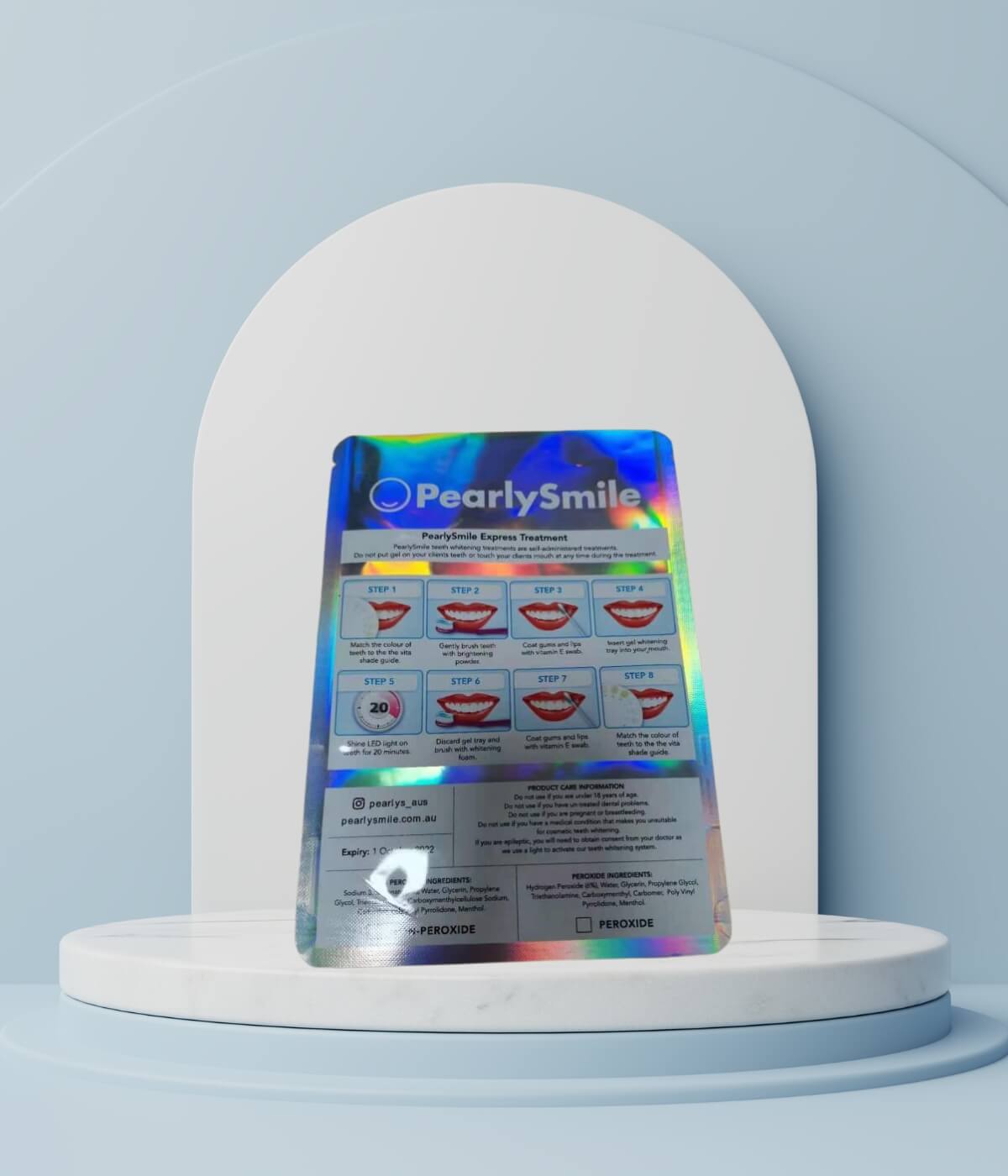

Rotogravure printing remains a popular choice for printing high-quality images on a wide range of materials. It is commonly used in the printing of magazines, packaging, and other printed materials that require high-resolution graphics and fine detail.

Rotogravure printer can produce ultra high-quality images with fine detail and sharpness. This makes it ideal for printing high-resolution graphics and images, such as those found in magazines and other publications. It is also capable of printing on a wide range of materials, including thin and delicate materials.

rotogravure printing is its high speed and efficiency. Because the cylinder is rotated at high speed, it can produce large volumes of printed material in a short amount of time. This makes it suitable for mass production of printed materials, such as newspapers and packaging.

Rotogravure printer can produce ultra high-quality images with fine detail and sharpness. This makes it ideal for printing high-resolution graphics and images, such as those found in magazines and other publications. It is also capable of printing on a wide range of materials, including thin and delicate materials.

rotogravure printing is its high speed and efficiency. Because the cylinder is rotated at high speed, it can produce large volumes of printed material in a short amount of time. This makes it suitable for mass production of printed materials, such as newspapers and packaging.

Rotogravure Printing Showcase

Compare

Packaging Printing Approaches Comparison

All these print methods are used to produce images on a variety of surfaces. Digital and UV printing uses digital technology to directly transfer an image onto a printing substrate, while flexo printing and gravure printing use printing plates to transfer the image onto the substrate.

Cost Efficiency

Setup Time

Plate Setup

Small Volumn

Short

No

Large Volumn

Slightly Long

Yes

Large Volumn

Moderate

Yes

Small Volumn

Very Short

No

Let's Connect