PLA Origin

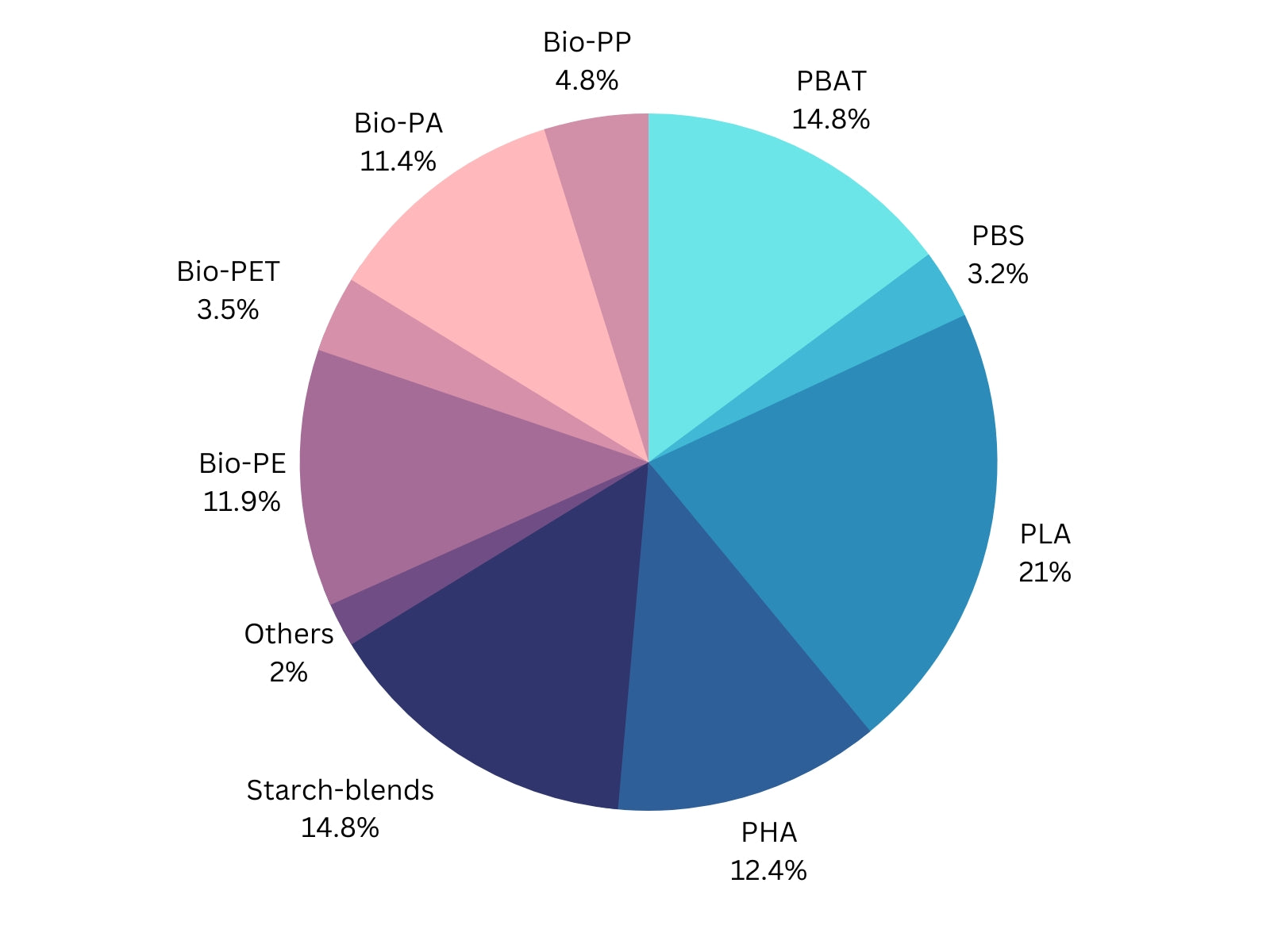

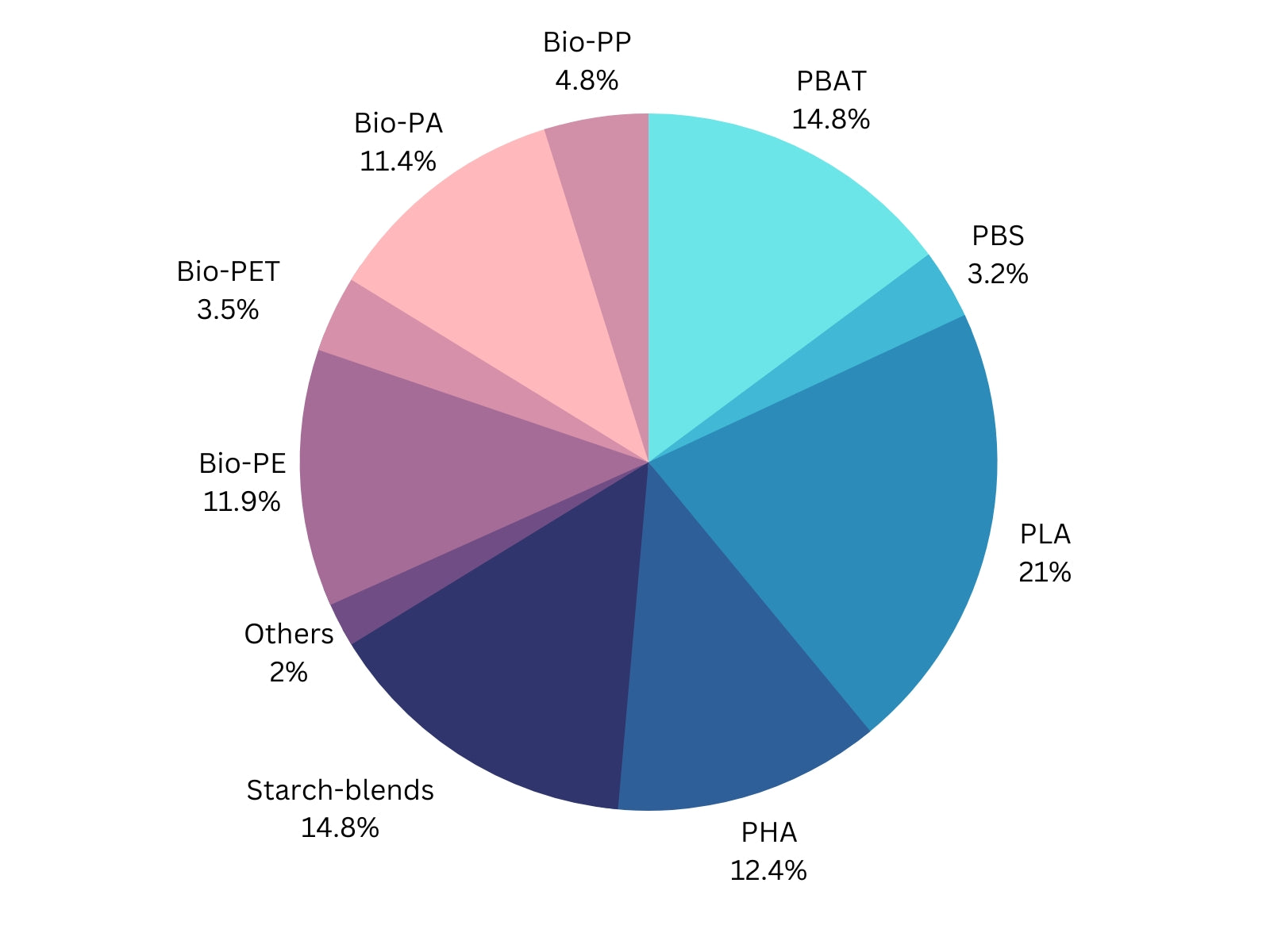

The global PLA market size has been dominating among other bioplastics options. And, packaging industry is the largest consumer of PLA, accounting for over 50% of the total demand.

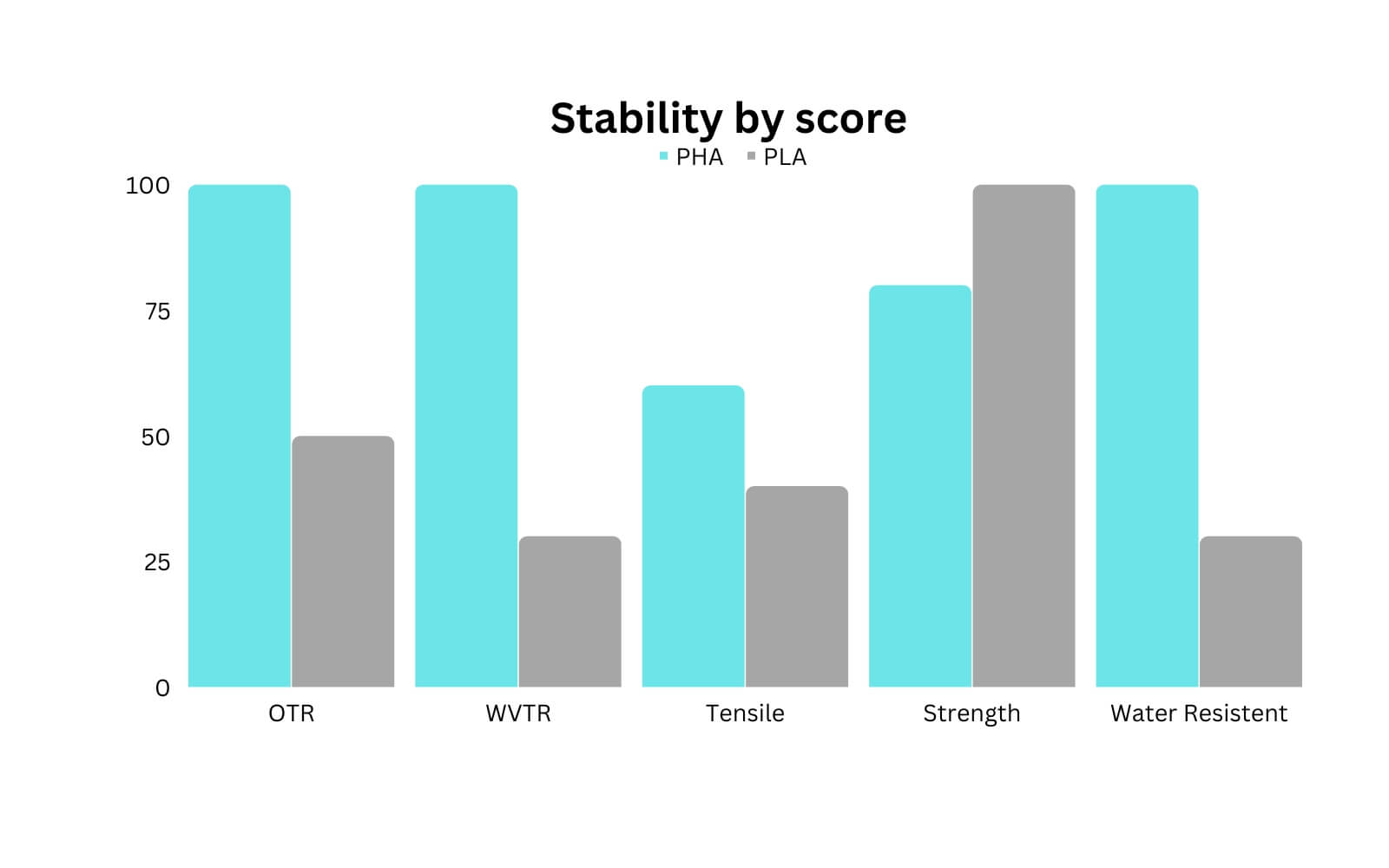

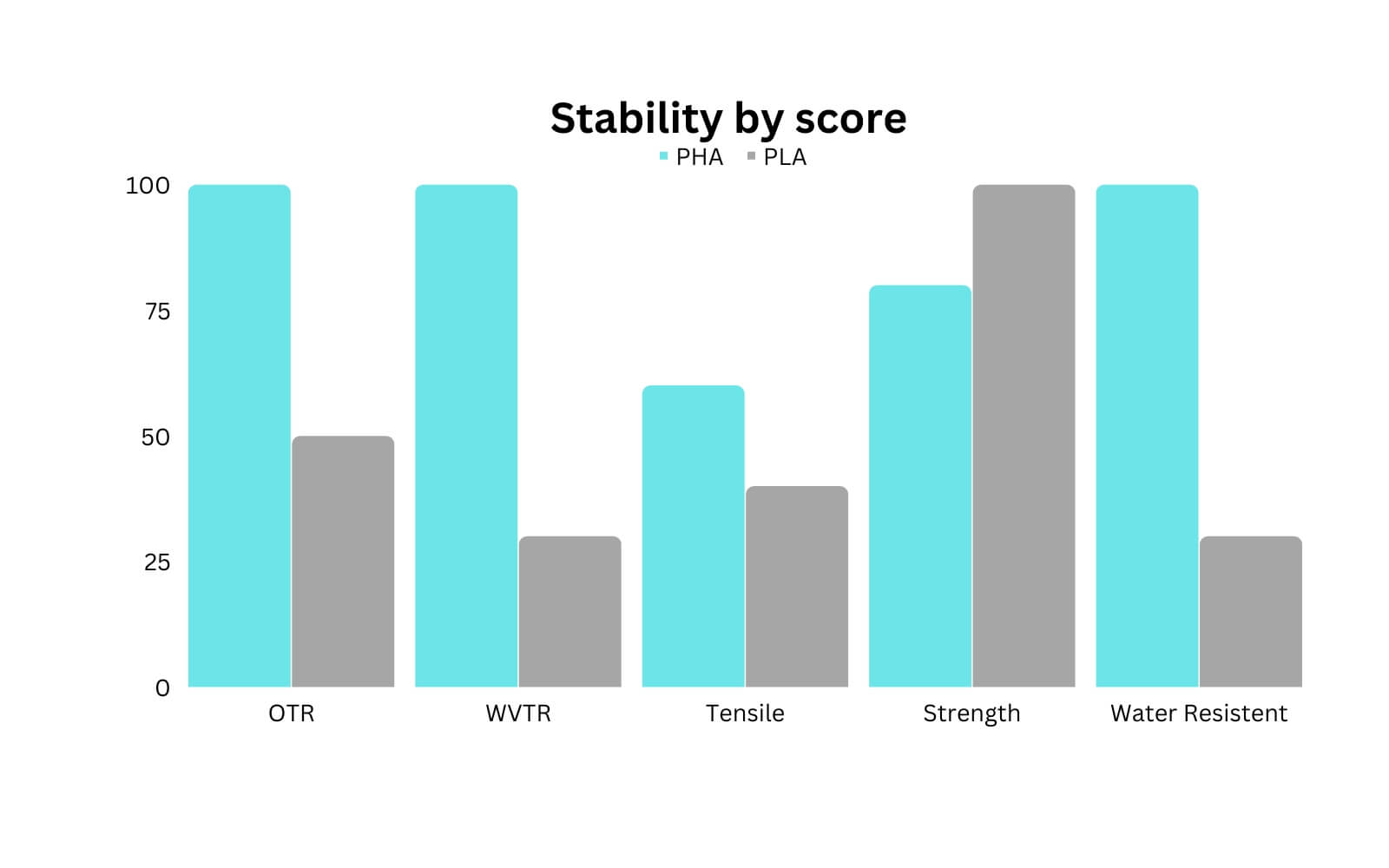

PLA has a relatively low melting point, so it can deform or melt at temperatures around 60-65°C (140-149°F). However, it can withstand higher temperatures for short periods of time, around 80-85°C (176-185°F), without significant degradation. PLA is stable in neutral or slightly acidic environments, but it can degrade in alkaline or highly acidic conditions. It is also susceptible to hydrolysis in the presence of water, which can cause the polymer chains to break down and weaken the material over time. It can degrade over time even without exposure to extreme temperatures or chemicals.

The global PLA market size has been dominating among other bioplastics options. And, packaging industry is the largest consumer of PLA, accounting for over 50% of the total demand.

PLA has a relatively low melting point, so it can deform or melt at temperatures around 60-65°C (140-149°F). However, it can withstand higher temperatures for short periods of time, around 80-85°C (176-185°F), without significant degradation. PLA is stable in neutral or slightly acidic environments, but it can degrade in alkaline or highly acidic conditions. It is also susceptible to hydrolysis in the presence of water, which can cause the polymer chains to break down and weaken the material over time. It can degrade over time even without exposure to extreme temperatures or chemicals.

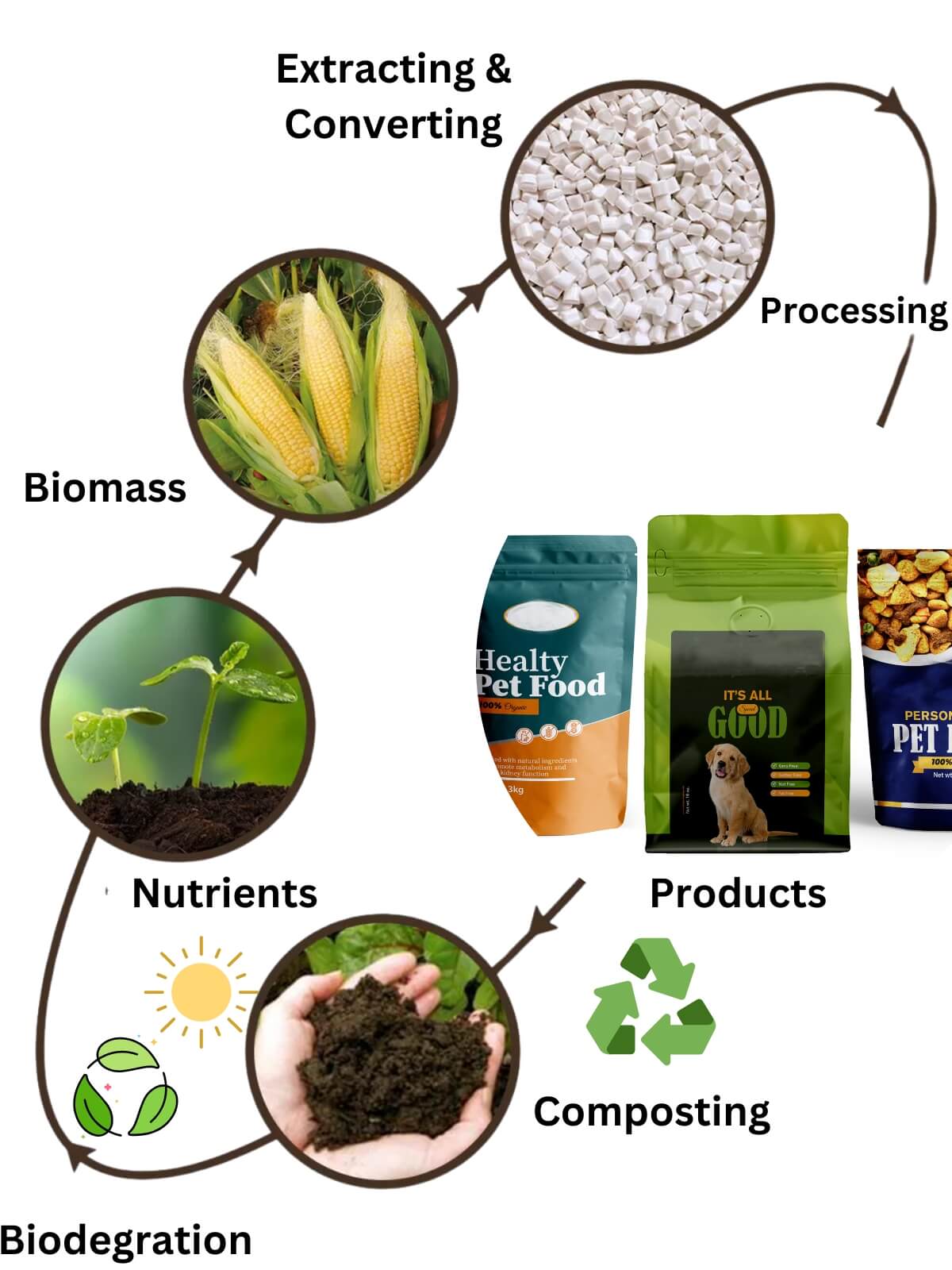

Our compostable plastics lifecycle aligns with the principles of a circular economy. The process begins with the use of biomass raw materials as nutrients for microorganisms. Through fermentation, extraction, downstream processing and other steps, final compostable packaging products are being produced. At the end of the product packaging useage, there will be several options for disposal, including recycling and reuse, composting, and biodegradation. This ensures that the materials used in the production of Anacotte compostable packaging products are recycled and composted with committment: reducing waste and environmental impact.

Compare

PLA properties

Eplore various potential implementations that can be derived from the concept of PLA.

Feature

Properties

Frequent Applications

Bio-baased

Transparency

Food Containers

Flexural strength

Heat Resistance

Degradable Plastics Bags

Tear Strength

Biodegradability

Coating Films

Better Strength

Stronger Barrier

Durable Films and Bags

Better Biodegradability

Robust Decompostability

Composite Materials

Durable, opaque, large compatibility, strong biodegradability

Strong Biodegradability

Multi-purpose

PLA Application in packaging

- Bottle

- Container

- Trays

- Tubes

- Lids

- and more..

- Films

- Bags

- Pouches

- mailers

- and more..