PHA Origin

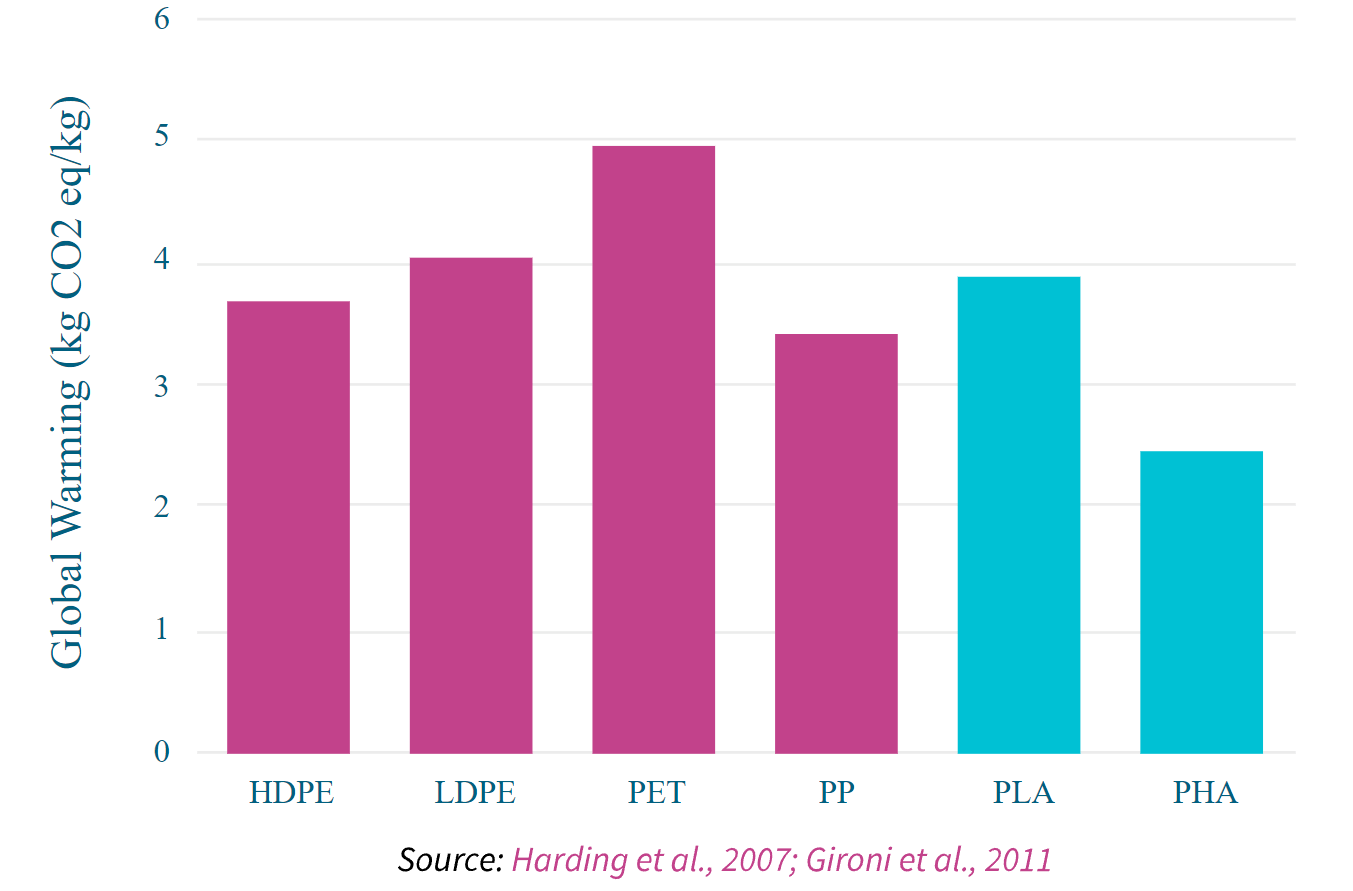

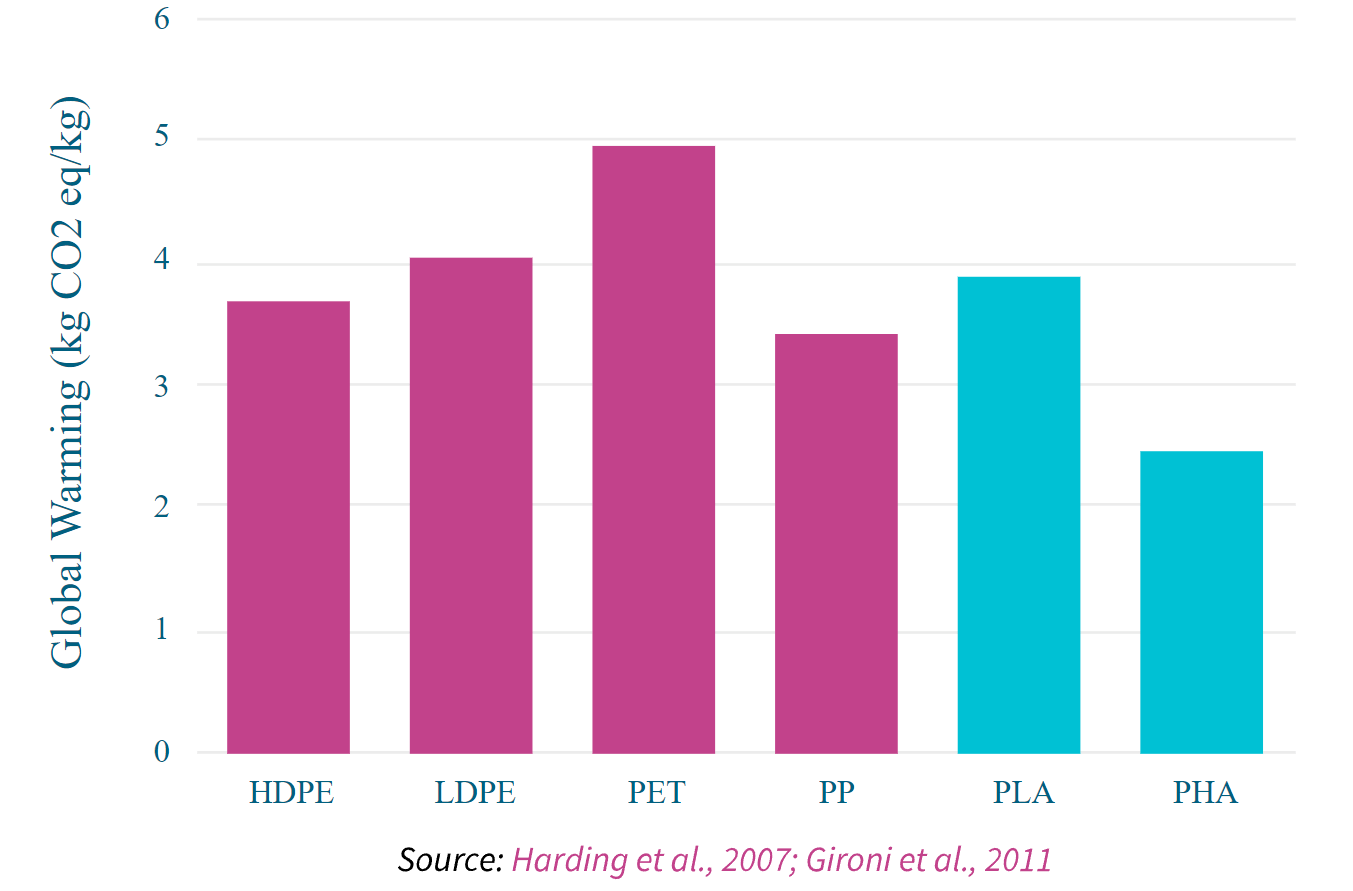

PHA redefines sustainability. The production of plastics is one of the leading sources of greenhouse gas emissions. While other bio-based alternatives to traditional plastic may be more sustainable from a climate perspective, PHA (polyhydroxyalkanoate) has significantly lower carbon emissions and energy requirements than all other bio-based polymers. This makes it a potentially valuable option for reducing the environmental impact of plastic production.

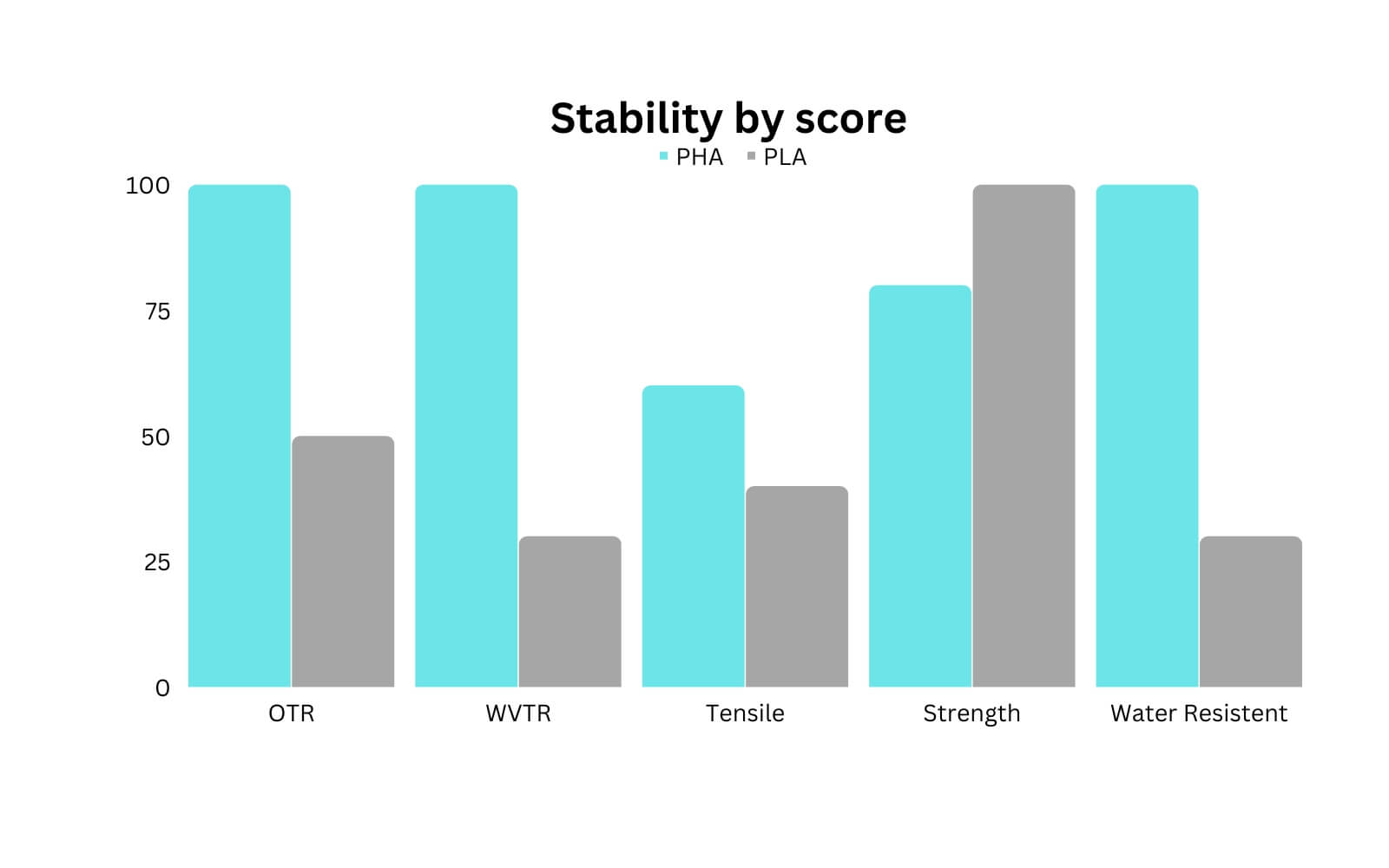

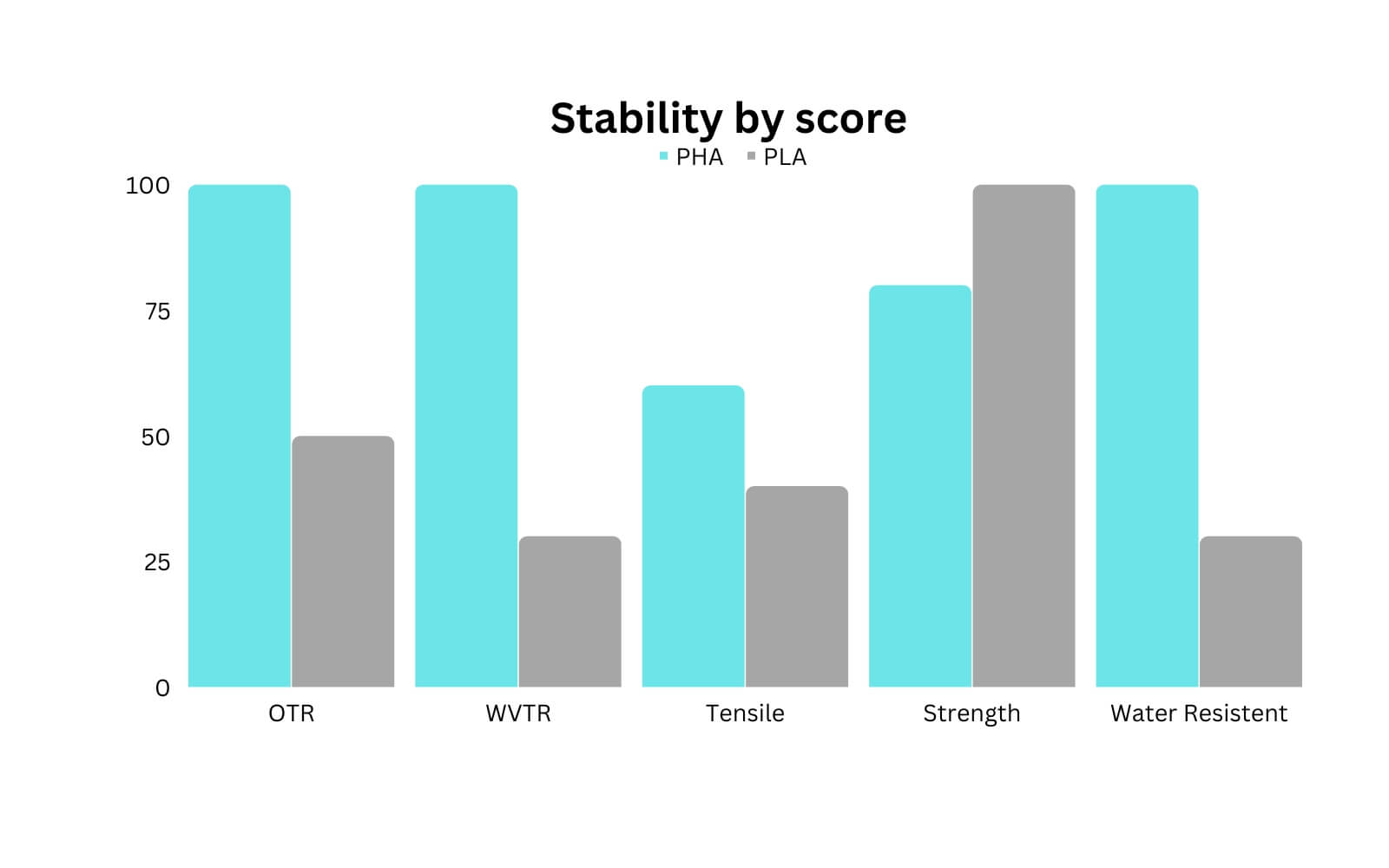

PHA is known for its hydrolytic stability and high heat deflection temperature, making it an attractive alternative to PLA in certain applications. PHA also has robust moisture and water resistance, rigidity, and gas barrier properties. In comparison, PLA is known for its toughness and transparency.

PHA redefines sustainability. The production of plastics is one of the leading sources of greenhouse gas emissions. While other bio-based alternatives to traditional plastic may be more sustainable from a climate perspective, PHA (polyhydroxyalkanoate) has significantly lower carbon emissions and energy requirements than all other bio-based polymers. This makes it a potentially valuable option for reducing the environmental impact of plastic production.

PHA is known for its hydrolytic stability and high heat deflection temperature, making it an attractive alternative to PLA in certain applications. PHA also has robust moisture and water resistance, rigidity, and gas barrier properties. In comparison, PLA is known for its toughness and transparency.

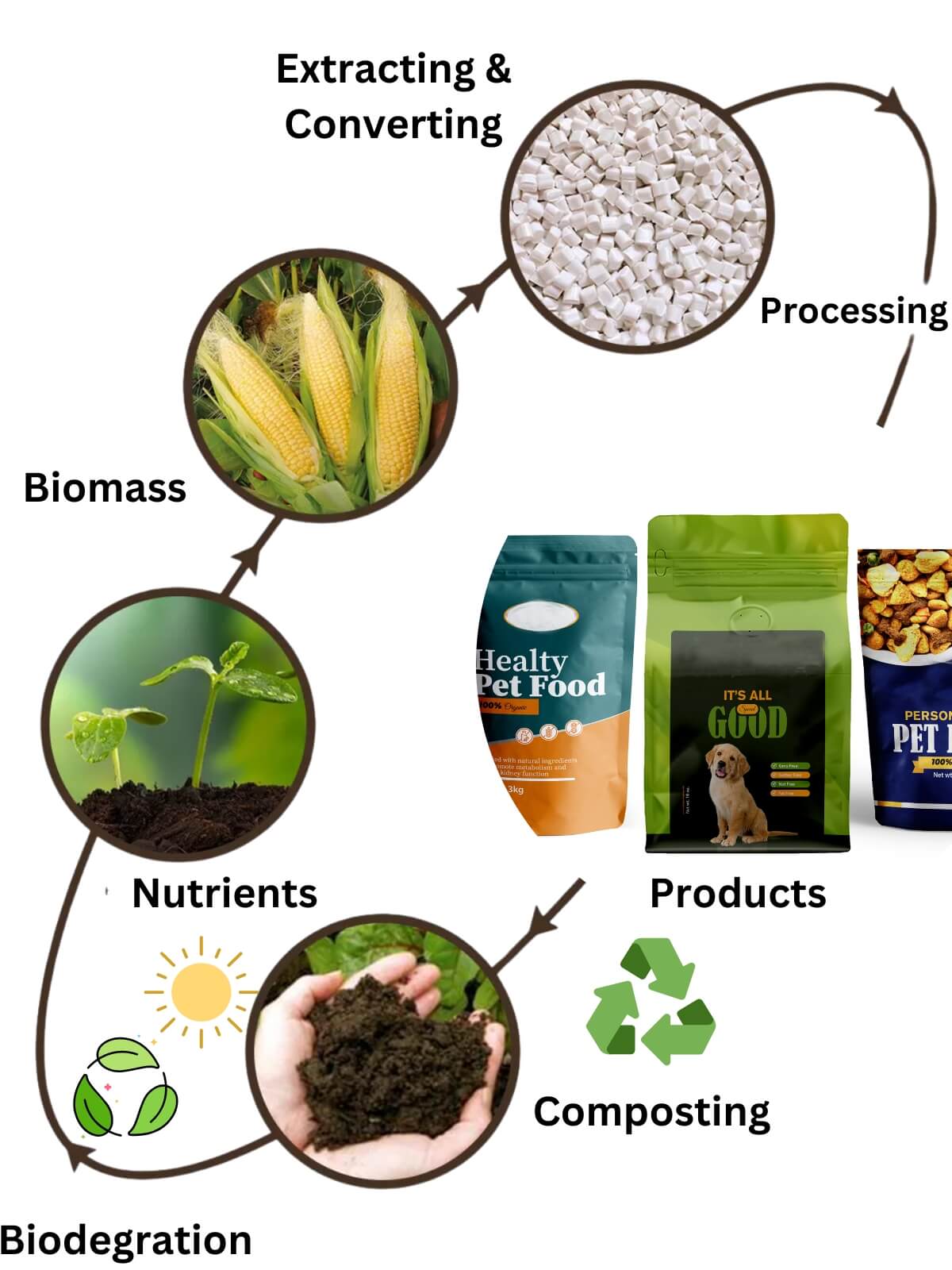

Our compostable plastics lifecycle aligns with the principles of a circular economy. The process begins with the use of biomass raw materials as nutrients for microorganisms. Through fermentation, extraction, downstream processing and other steps, final compostable packaging products are being produced. At the end of the product packaging useage, there will be several options for disposal, including recycling and reuse, composting, and biodegradation. This ensures that the materials used in the production of Anacotte compostable packaging products are recycled and composted with committment: reducing waste and environmental impact.

PHA Application in packaging

- Bottle

- Container

- Tubes

- and more..

- Films

- Bags

- Pouches

- mailers

- and more..