Quick Turnaround

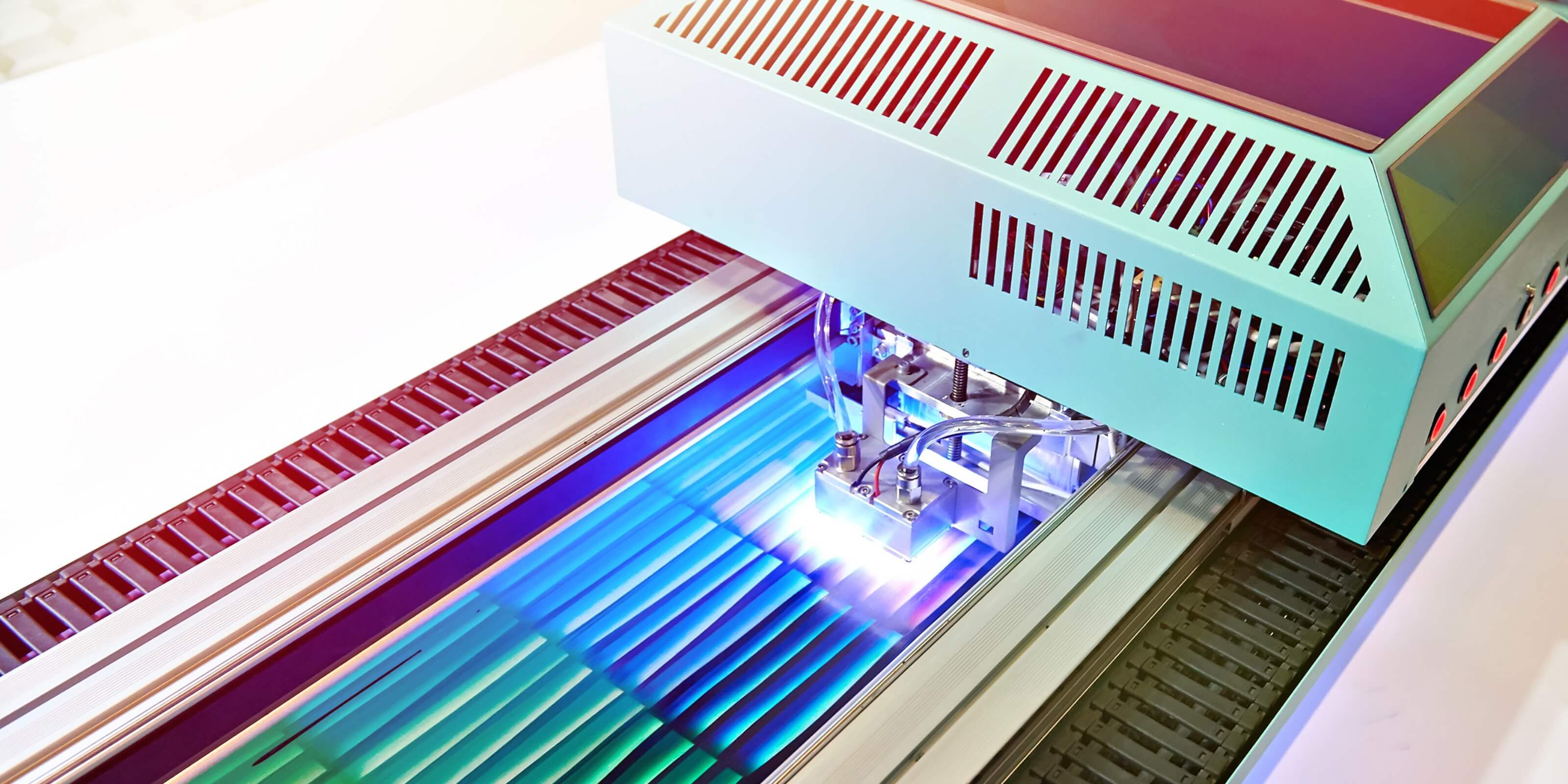

We are adopting UV printing to offer a wider range of packaging options that are not only visually appealing, but also highly durable and resistant to wear and tear. UV printing can be used to print intricate designs and patterns on packaging materials, making them stand out on store shelves and grab the attention of potential customers.

UV printing is a type of digital printing that uses ultra-violet light to cure inks and coatings, resulting in high-quality prints with vibrant colors and sharp details. Unlike traditional printing methods that use heat to dry inks, UV printing cures the inks almost instantly, making it ideal for printing on a wide range of materials including plastic, metal, glass, and even flexible substrates.

UV printing offers several benefits over traditional printing methods, including faster drying times, improved color accuracy and vibrancy, and the ability to print on a wider variety of materials. Additionally, UV inks are more durable and resistant to fading and scratching, making them a popular choice for printing on items that will be handled or used frequently.

UV printing also offers environmental benefits over traditional printing methods. Since UV inks are cured instantly, there is no need to use solvents or other chemicals to dry the inks. This not only reduces the environmental impact of the printing process, but also makes it safer for workers and reduces the risk of fire and other hazards.

UV printing is a type of digital printing that uses ultra-violet light to cure inks and coatings, resulting in high-quality prints with vibrant colors and sharp details. Unlike traditional printing methods that use heat to dry inks, UV printing cures the inks almost instantly, making it ideal for printing on a wide range of materials including plastic, metal, glass, and even flexible substrates.

UV printing offers several benefits over traditional printing methods, including faster drying times, improved color accuracy and vibrancy, and the ability to print on a wider variety of materials. Additionally, UV inks are more durable and resistant to fading and scratching, making them a popular choice for printing on items that will be handled or used frequently.

UV printing also offers environmental benefits over traditional printing methods. Since UV inks are cured instantly, there is no need to use solvents or other chemicals to dry the inks. This not only reduces the environmental impact of the printing process, but also makes it safer for workers and reduces the risk of fire and other hazards.

Compare

Packaging Printing Methods Comparison

All these print methods are used to produce images on a variety of surfaces. Digital and UV printing uses digital technology to directly transfer an image onto a printing substrate, while flexo printing and gravure printing use printing plates to transfer the image onto the substrate.

Cost Efficiency

Setup Time

Plate Setup

Small Volumn

Short

No

Large Volumn

Slightly Long

Yes

Large Volumn

Moderate

Yes

Small Volumn

Very Short

No

Compare

Product specification

Give your customers useful information about your products and showcase differences between them.

Yes

No

Yes

Yes

No

Yes

No

No

UV Printing

Application

UV Printing technology has a great number of applications in a variety of industries.

UV printing is often used in the production of packaging materials, such as boxes, labels, and flexible packaging. It allows for high-quality printing on a variety of materials, including paper, film, and foil.

UV printing is a popular choice for the production of signs, banners, and other graphics. It allows for the printing of high-resolution images with vibrant colors, and the inks are resistant to fading and discoloration.

UV printing is used in a variety of industrial applications, including the printing of circuit boards, medical devices, and automotive parts. It allows for precise printing on a variety of materials, including plastics and metals.

UV printing is often used to print on non-porous surfaces, such as glass, ceramic, and metal. It allows for high-quality printing on these surfaces without the ink soaking into the material.

UV printing is used in the production of decorative items, such as wallpaper, flooring, and furniture. It allows for the printing of high-quality images and patterns on a variety of materials, including textiles and plastics.

Send us a message

Start your UV Printing Project

Fill in the details and we will get back to your messsage as soon as we can.