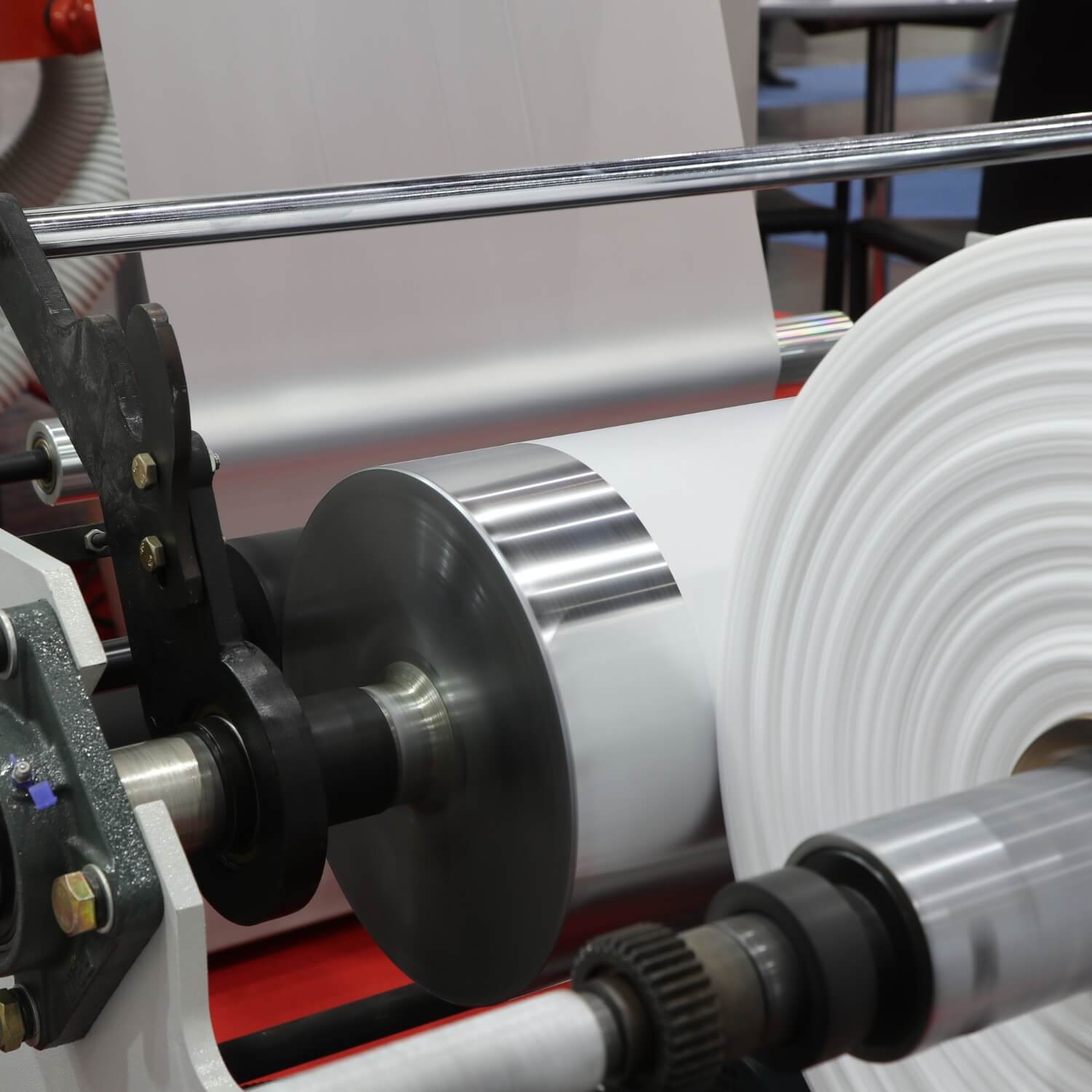

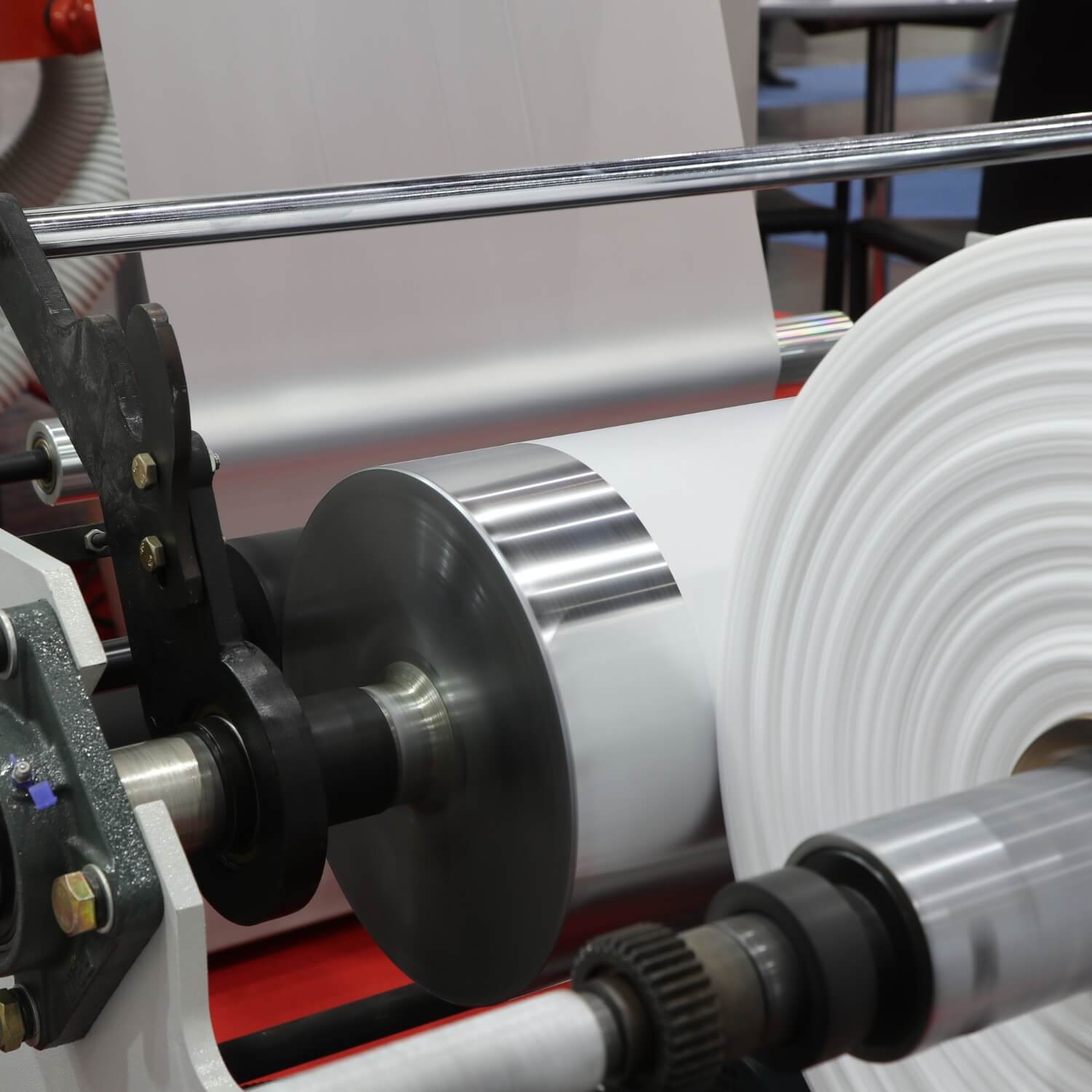

Extrusion Lamination

Extrusion lamination is by applying a layer of adhesive and extruded between two or more layers of material. The layers are then bonded together under heat and pressure. This method is typically used to laminate a variety of different materials, such as paper, film, and foil. When compared to other lamination methods, such as adhesive lamination, solvent-based lamination, and water based lamination, extrusion lamination has the advantage of being versatile and cost-effective. However, it also has the disadvantage of requiring costly setup which makes it not suitable for short-run projects. Co-extrusion lamination is also a faster and more efficient method, and can create multilayer films with specific properties. However, it can only be used to laminate a single type of material, such as film.

Process

The process involves the following steps:

1. The layers of material to be laminated are fed into an extruder where they are heated to a high temperature.

2. A layer of adhesive is then extruded between the layers of material. The adhesive is usually a polymer, such as polyethylene, that is melted and extruded in a thin layer.

3. The layers of material and adhesive are then passed through a set of nip rollers which apply pressure to the laminate and bond the layers together.

4. The laminate is cooled and wound up into a roll ready for further processing or packaging.

The outcome will be a single, cohesive package with excellent barrier properties, strength and printability.

Application and Example Capabilities for Solvent Based Laination

Click here for water based lamination

Click here for non-solvent based lamination

Click here for solvent based lamination

Learn about the materialsMaterial Structure

Reference

NY/AL/extPE/PE

PET(NY, OPP)/extPE/PE

KOP(KNY)/extPE/PE

PET/VMPET/extPE/PE

ExtPE stands for "extruded polyethylene". It is a type of polyethylene that is produced by extrusion process: by melted and forced through a die to create a shape, such as a film, sheet, or tubing.

VMPET/extPE/PE

OPP/extPE/PE

OPP/EVOH/extPE

OPP/exPP

exPP stands for "extruded polypropylene". In the case of exPP, the polypropylene is melted and forced through a die to create a film or sheet. The exPP film or sheet can then be used for a wide range of applications, such as packa

Comparing

Extrusion and Co-extrusion

Extrusion lamination:

In this method, a layer of adhesive is extruded between two or more layers of material, and the layers are then bonded together under heat and pressure. This method is typically used to laminate a variety of different materials, such as paper, film, and foil.

Co-extrusion lamination:

In this method, multiple layers of material are extruded simultaneously, and are then bonded together as they are extruded. This method is typically used to laminate a single type of material, such as film, and is often used to create multilayer films with specific properties. Learn more about co-extrusion lamination by clicking here.

In this method, a layer of adhesive is extruded between two or more layers of material, and the layers are then bonded together under heat and pressure. This method is typically used to laminate a variety of different materials, such as paper, film, and foil.

In this method, multiple layers of material are extruded simultaneously, and are then bonded together as they are extruded. This method is typically used to laminate a single type of material, such as film, and is often used to create multilayer films with specific properties. Learn more about co-extrusion lamination by clicking here.

- It is a cost-effective method of lamination

- Can be used to bond a wide variety of materials

- Can create a strong and durable bond between layers

- Can be used to create a wide range of products

- It can be used to improve printability and aesthetics of the final product

- It can be used to add barrier properties to the final product

- It requires a specialized equipment and skilled personnel to operate

- The process requires high temperatures, which can cause some materials to degrade

- It can be difficult to control the thickness of the adhesive layer, which can affect the final properties of the product.

Let's Connect